weighted pendulum for impact testing|instron impact tester : manufacturers Pendulum impact testing machines are critical to validating the performance of polymer, composite, and light alloy materials when subjected to an impact. Selecting the right pendulum for the application is key to maximizing throughput, repeatability, and operator safety. This guide . WEBLegenda: Português. Formato: MKV. Qualidade: BluRay. Tamanho: 2.10 GB. Qualidade de Áudio: 10. Qualidade de Vídeo: 10. Sinopse. Filme Jogada de Rei Dual Áudio para .

{plog:ftitle_list}

Resultado da Ultime notizie e aggiornamenti in tempo reale dal mondo dello sport. Ultima ora calcio, basket, ciclismo, tennis dalla redazione della Gazzetta dello Sport.

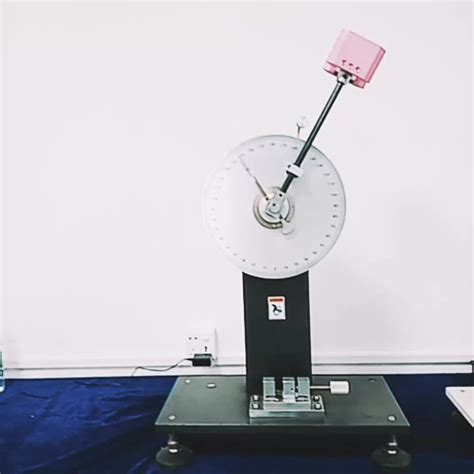

Pendulum impact testing machines are critical to validating the performance of polymer, composite, and light alloy materials when subjected to an impact. Selecting the right pendulum for the application is key to maximizing throughput, repeatability, and operator safety. This guide .Instron pendulums are designed to meet the growing demand for accurate and .

Instrumented drop weight and pendulum testing is considered to be the best . The drop-weight impact test, also known as the Pellini test, uses a weight suspended over a simply supported horizontal test specimen and then dropped to produce the impact. A tube or rails guide the weight during its “free .Instron pendulums are designed to meet the growing demand for accurate and repeatable impact testing on a wide range of materials. Impact resistance is one of the most important properties for component designers to consider. It is a .A pendulum impact testing device, or a pendulum impact tester, is a contraption with a swaying pendulum that is released to produce impact on a secured specimen. The pendulum is fitted with a weighted hammer attached to its end, .

With our HIT series pendulum impact testers for tests on plastics up to 50 joules, ZwickRoell offers a particularly precise, while also economical solution for the polymer industry: Charpy tests: ISO 179, ASTM D6110. Izod tests: ISO .Our product line includes pendulum impact testers for metals and pendulum impact testers for plastics, drop weight testers with an energy range of only a few joules to 100,000 joules, as well as hydraulic high-speed testing machines.In addition to tensile and flexure tests, Charpy impact tests are the most frequently performed mechanical tests in the polymer industry. ZwickRoell’s HIT series pendulum impact testers offer a high-precision, cost effective solution.

Pendulum impact testing machines are critical to validating the performance of polymer, composite, and light alloy materials under real-life conditions. Selecting the correct pendulum .Pendulum impact tester HIT450P 1962 849 1703 1950 2400 2317 2000 1490 500 800 150 450 188 Pendulum impact tester HIT450P, dimension Applications The HIT450P / HIT300P is a universal pendulum impact testing machine that can be used for a wide range of test types. Due to its modularity and comprehensive range of accessories it is suitable for .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and .

pendulum impact tester price

The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away .Pendulum Impact Testing machines and Drop Weight Testers are both critical to validating the performance of materials. However, there are differences between the two instruments that determine which application is best suited to each. Difference between a Pendulum Impact Testing machine and a Drop Weight Tester. Each test uses a different approach.

An impact test consists of a striker hitting the test specimen to transfer a large force in a short time.You can use a drop tower or a pendulum tester to achieve such large forces.. A striker is dropped vertically from a height for a drop tower test and uses gravity to achieve the necessary impact energy. Similarly, in a pendulum test, the striker is fixed to an arm that swings like a .

The Instron MPX motorized pendulum impact test system with the new Bluehill Impact software is the preferred system for metals impact testing to Charpy and Izod standards. Available in capacities ranging from 300 to 900 Joules, the MPX is efficient and easy to operate, making it suitable for high volume testing.

Pendulum Charpy/Izod Impact Testing is a high strain-rate test to determine the amount of energy absorbed by a material during fracture.The Impact tester involves a pendulum of known mass and length which is dropped from a known height to strike an Impact Specimen. . quantify the energy absorbed by a material upon impact, while drop-weight .

Instron is always available to provide further guidance and help you identify the correct test method for a specific material. Step 2: Know your standards. Once you have identified the correct pendulum hammer impact test method, always refer to the relevant industry standard. ISO 179 and ASTM D6110 cover the Charpy pendulum impact test.Instron Dynatup drop weigh impact testing machine next generation is the Instron 9400 Series. A drop weight impact testing machine is used to determine the energy required to break or damage a material in which a defined weight falls onto a specimen or a component from a specific height and with a specific impact energy and velocity.The testing systems used for these tests are either pendulum impact testers or drop-weight testers. Because many materials used for a number of different applications on a daily basis are subjected to fluctuating temperatures, and since the fracture or failure behavior also depends on temperature, these materials must often be tested in their .

Find out more about ZwickRoell‘s pendulum impact tester product range and its levels of automation. 2 Product features of the HIT pendulum impact testers 4 Learn about the different functions and advantages of HIT pendulum impact testers. 3 Applications in the world of impact testing 10 3.1 Charpy tests 10 3.2 Izod tests 11 Drop weight impact test standards. ASTM E208, ASTM D7136, ASTM D3763, ASTM F1459. ISO 6603-2, ISO 3127, ISO 13356. . Application: In impact testing, momentum helps analyze the collision between the pendulum (or weight) and the specimen, influencing the material's response. Stress (σ) Abstract Pendulum impact testing is widely known to have a history that extends back to the turn of the last century. To many researchers today, instrumentation of the impact test to acquire a load-time history, and thereby provide important data in addition to absorbed energy, is usually considered to be a relatively recent development.

Impact test conditions were chosen to represent those most severe relative to the potential for fracture, namely, (1) deformation at a relatively low temperature, (2) a high strain rate (i.e., rate of . an impact blow from a weighted pendulum hammer that is released from a cocked position at a fixed height "h". The specimen is positioned at . The Charpy impact test is a high strain-rate test to find the impact toughness of a material. In the Charpy impact test, a standard notched specimen is struck by a controlled weight pendulum swung from a predefined height. . After the first test, you can increase the weight of the pendulum’s hammer until it breaks the material, which would then signify that the impact strength value can be calculated. If you need to do an IZOD test in cold .

Every time a pendulum impact testing machine provides high spread of results, the progress with materials research is affected. It is not difficult to understand that lab environments with several operators have a major .In addition to the high energy impact models, Tinius Olsen manufactures a range of low energy pendulum impact testers that can also be easily changed from a Charpy to an Izod configuration. These testers come in a couple of capacities and are designed primarily for either plastics or metals impact testing.Pendulum Impact Method In the pendulum impact method, an impact bending load is applied to the specimen by a device attached to the pendulum near its center of percus-sion. The pendulum is weighted to provide the required capacity. The energy absorbed in breaking the specimen is determined by observing the

There are basically two types of impact tests: pendulum and drop weight. Izod, Charpy, and tensile impact are the most common of the pendulum type tests. Pendulum Testing. The first attempts at obtaining this value were done by means of a swing pendulum. A pendulum of a known weight is hoisted to a known height on the opposite side of a pivot .A brief history of plastics impact testing. To detect material behaviors at high deformation speeds, impact testing is employed. Pendulum impact testers, high-speed testing equipment, and drop weight testers are all used to determine how plastics behave under impact loading.. In the past, choosing between drop weight and pendulum impact testers appeared .

Abstract: Pendulum impact testing is widely known to have a history that extends back to the turn of the last century. To many researchers today, instrumentation of the impact . Therefore, Gagarin built a drop-weight machine equipped with a striker of mass at least 10 kg. Apparently, he was able to test a number of different specimen .The most common configuration for pendulum impact test are Izod and Charpy ones. The scope of these impact test is to measure the answer of a standard test specimen to the pendulum-type impact load. The result is expressed in term of kinetic energy consumed by the pendulum in order to break the specimen. The energy

When performing a Charpy impact test, a weighted pendulum is dropped from a certain height with the purpose of making contact with the chosen specimen. This material would then absorb energy, which can be inferred by measuring the pendulum’s height before and after it was fractured and then getting the difference between the two measurements.

pendulum impact tester machine

The Charpy or the Izod impact test is carried out by testers using a pendulum impact testing apparatus. A device having a swinging pendulum that is released to strike a secured specimen is referred to as a pendulum impact testing machine or a pendulum impact tester. A weighted hammer on the end of the pendulum strikes the sample material.

The Coesfeld pendulum impact tester enables testing of the entire spectrum of plastic impact testing, Charpy, Izod, impact tensile and Dynstat according to ISO as well as ASTM standards up to 50 joules. Optionally, the instrument can be upgraded with automatic pendulum return and specimen loading, for convenient and high throughput. The pendulum impact tester is . useful in the development of a standardized test method for Charpy impact testing of cementitious composites. The Charpy Test The Charpy impact test relies on the potential energy of a weighted pendulum as shown in Fig. 1. The pendulum is raised to some initial height h i, which is measured from the center of mass to the datum.

white label Impact Testing

bulk Impact Testing

OEM Impact Testing

pendulum impact tester

ETFs - Investidor10 - Ações, Cotação e Indicadores Fundam.

weighted pendulum for impact testing|instron impact tester